Njengombhobho osetyenziswa ngokubanzi, umbhobho we-iron ductile udlala indima ebalulekileyo kwimimandla emininzi. Nangona kunjalo, umlinganiselo wesantya sesandi se-ultrasonic ubonelela ngendlela eyaziwayo kunye nethembekileyo yokuqinisekisa ukuthembeka kwezinto eziphathekayo.

1. Umbhobho wentsimbi yentsimbi kunye nokusetyenziswa kwayo

I-DINSENumbhobho wentsimbingumbhobho owenziwe ngentsimbi ye-ductile ngenkqubo yokuphosa i-centrifugal. Ineenzuzo zamandla aphezulu, ukuqina okuphezulu, ukuxhathisa kwe-corrosion, ukumelana noxinzelelo oluphezulu, njl., kwaye isetyenziswa ngokubanzi kunikezelo lwamanzi ezidolophini, ukuhambisa amanzi, ukuhanjiswa kwegesi kunye nezinye iindawo.

Kwiinkqubo zokubonelela ngamanzi asezidolophini, imibhobho yentsimbi ye-ductile inokumelana noxinzelelo oluphezulu lwamanzi ukuqinisekisa ukuthuthwa okukhuselekileyo kobutyebi bamanzi. Ukunganyangeki kwayo kakuhle kokuthotywa kwayo kukwenza ukuba ingachaphazeleki kakhulu kukhukuliseko ngenxa yobumdaka obusemanzini ngexesha lokusetyenziswa kwexesha elide, ukwandisa ubomi benkonzo yombhobho. Kwinkqubo yokuhambisa amanzi, amandla aphezulu kunye nokuqina kweemibhobho yensimbi ye-ductile inokumelana nokutshitshiswa kwamanzi amdaka kunye nesenzo samandla angaphandle ukuze kuqinisekiswe ukusebenza okuzinzile kwenkqubo yokuhambisa amanzi. Ukongezelela, imibhobho yentsimbi ye-ductile nayo idlala indima ebalulekileyo kwiinkalo ezifana nokuhanjiswa kwegesi. Ukutywinwa kwabo okulungileyo kunokuthintela ngokufanelekileyo ukuvuza kwegesi kunye nokukhusela ubomi babantu kunye nepropathi.

2. Iindlela kunye nezizathu zokubona izinga le-spheroidization yeepayipi zensimbi ze-ductile

Iindlela zokufumanisa

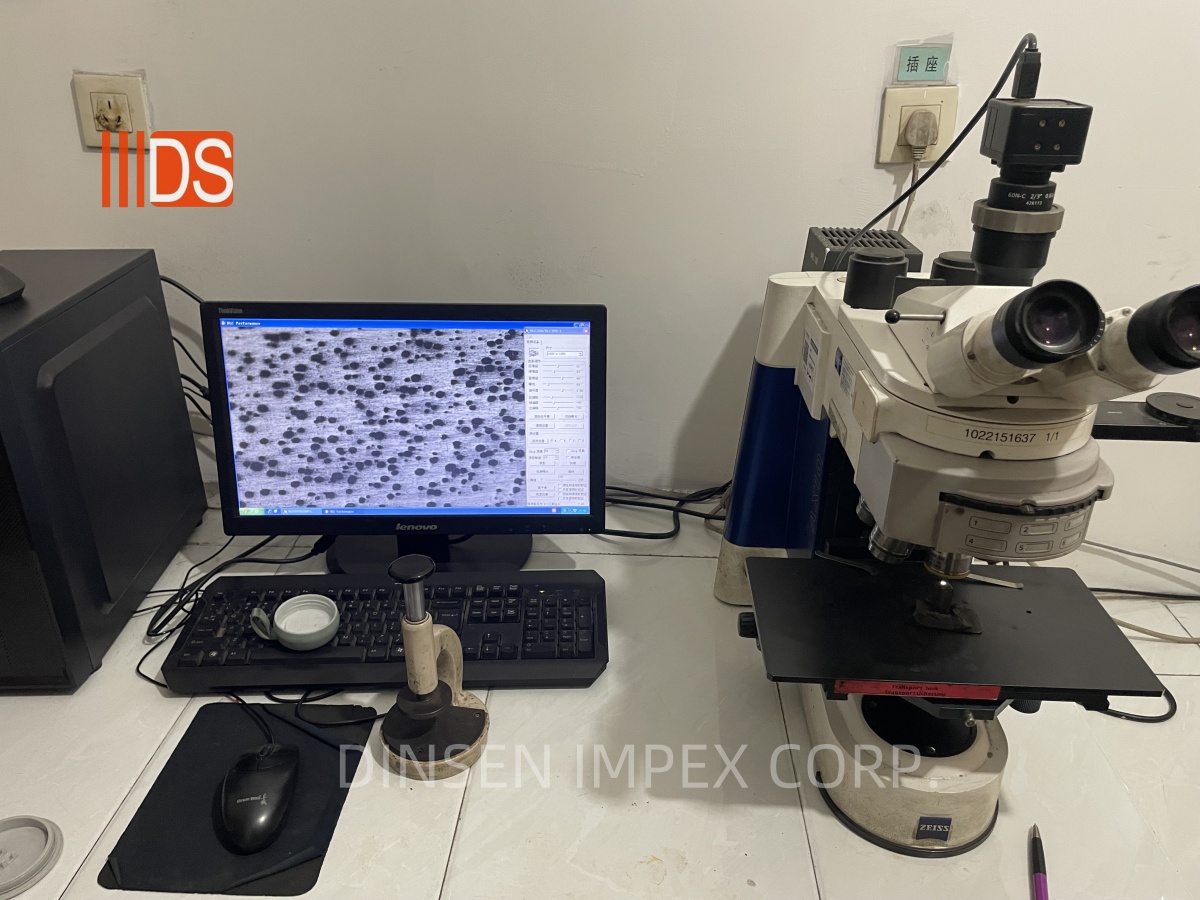

Indlela yokuhlalutya i-Metallographic: Le yindlela esetyenziswa ngokuqhelekileyo yokukhangela izinga le-spheroidization. Ngokulungiselela iisampulu ze-metallographic zemibhobho yentsimbi ye-ductile, i-morphology kunye nokuhanjiswa kwegraphite kubonwa phantsi kwe-microscope ukumisela izinga le-spheroidization. Amanyathelo athile abandakanya iisampulu, ukufaka inlaying, ukucola, ukugudisa, ukubola kunye nokuqwalaselwa. Indlela yokuhlalutya i-metallographic inokubona ngokucacileyo idigri ye-spheroidization yegraphite, kodwa umsebenzi unzima kwaye ufuna izixhobo zobuchwephesha kunye neengcali.

Indlela yokufumanisa i-Ultrasonic: Izinga le-spheroidization lifunyenwe ngokusebenzisa iimpawu zokusasazwa kwamaza e-ultrasonic kwimibhobho yensimbi ye-ductile. Isantya sokusasaza kunye nokunciphisa amaza e-ultrasonic kwi-ductile iron kunye needigri ezahlukeneyo ze-spheroidization ziyahluka. Ngokulinganisa iiparamitha zamaza e-ultrasonic, izinga le-spheroidization linokuchazwa. Le ndlela ineenzuzo zokukhawuleza, ukungonakalisi kunye nokuchaneka, kodwa idinga izixhobo zokufumanisa i-ultrasonic yobuchwephesha kunye nesofthiwe.

Indlela yokuhlalutya i-Thermal: Izinga le-spheroidization lichongwa ngokulinganisa utshintsho lwe-thermal ye-ductile iron pipes ngexesha lokupholisa. I-Ductile iron ene-spheroidization elungileyo iya kuba neejika ezithile zokutshintsha kwe-thermal ngexesha lokupholisa. Ngokuhlalutya la magophe, izinga le-spheroidization lingamiselwa. Uhlalutyo lwe-thermal lunenzuzo yokusebenza okulula kunye nesantya esikhawulezayo, kodwa ukuchaneka kwayo kuncinci.

Isizathu sovavanyo

Qinisekisa umgangatho wemveliso: Isantya se-Spheroidization sesinye sezibonakaliso ezibalulekileyo zomgangatho wombhobho wentsimbi ye-ductile. Ukuphakama kwesantya se-spheroidization, ngcono amandla, ukuqina kunye nokumelana nokubola kombhobho. Ngokuvavanya umlinganiselo we-spheroidization, unokuqinisekiswa ukuba umgangatho wemibhobho yensimbi ye-ductile uhlangabezana neemfuno eziqhelekileyo kwaye unikezela abasebenzisi ngeemveliso ezithembekileyo.

Lungiselela inkqubo yokuvelisa: Iziphumo zovavanyo lwesantya se-spheroidization zinokubuyiselwa kubavelisi ukubanceda ukuba baphucule inkqubo yemveliso. Ngokomzekelo, ukuba izinga le-spheroidization liphantsi, inani le-spheroidizer elongeziweyo, ubushushu bokuphosa kunye nezinye iiparameters zinokuhlengahlengiswa ukwandisa izinga le-spheroidization, ngaloo ndlela kuphuculwe umgangatho wemveliso.

Ukuhlangabezana neemfuno zabathengi: Kwezinye iindawo ezikhethekileyo, ezifana nokuhanjiswa kwegesi ephezulu, izinga le-spheroidization lemibhobho yentsimbi ye-ductile iphezulu kakhulu. Ngokuvavanya izinga le-spheroidization, kunokwenzeka ukuhlangabezana neemfuno ezithile zabathengi kunye nokuphucula ukukhuphisana kweemarike zeemveliso.

3. I-laboratory ye-DINSEN ibonelela nge-ductile iron pipe spheroidization rate rate kubathengi baseRashiya

Kwiveki ephelileyo, ilabhoratri ye-DINSEN ibonelele ngeenkonzo zovavanyo lombhobho we-iron ductile spheroidization kubathengi baseRussia. Emva kokufumana ikhomishini yomthengi, ngokukhawuleza saququzelela iqela lobugcisa lobuchwephesha kwaye saphuhlisa isicwangciso sovavanyo oluneenkcukacha.

Okokuqala, sasebenzisa indibaniselwano yohlalutyo lwe-metallographic kunye novavanyo lwe-ultrasonic ukwenza uvavanyo olubanzi lwepayipi yentsimbi ye-ductile. Iziphumo zohlalutyo lwe-metallographic zibonise ukuba igraphite kumbhobho wentsimbi ye-ductile ine-morphology enhle kunye nesantya esiphezulu se-spheroidization. Iziphumo zovavanyo lwe-ultrasonic nazo zihambelana neziphumo zokuhlalutya i-metallographic, ziqinisekisa ngakumbi ukuchaneka kweziphumo zovavanyo.

Okwesibini, sinikeze umxhasi ingxelo yovavanyo olucacileyo, kubandakanywa indlela yokuvavanya, iziphumo zovavanyo, izigqibo zokuhlalutya, njl. Umxhasi wanelisekile kakhulu ngenkonzo yethu yokuvavanya kwaye wathi uya kuqhubeka esebenzisana nathi.

Ngale nkonzo yovavanyo, asinikanga kuphela abathengi baseRussia iziphumo zovavanyo olukumgangatho ophezulu, kodwa siqokelele amava atyebileyo ekuvavanyeni izinga le-spheroidization lemibhobho yentsimbi. Siya kuqhubeka sisebenza nzima ukubonelela abathengi ngeenkonzo zovavanyo ezinobungcali kunye nokusebenza kakuhle kunye negalelo kuphuhliso lweshishini lombhobho wentsimbi.

Ngamafutshane, uvavanyo lwe-spheroidization yezinga lemibhobho yensimbi ye-ductile yindlela ebalulekileyo yokuqinisekisa umgangatho wemveliso, ukwandisa iinkqubo zokuvelisa, kunye nokuhlangabezana neemfuno zabathengi.I-DINSENILebhu iya kuqhubeka nokubonelela abathengi ngeenkonzo zovavanyo lobuchwephesha kunye negalelo kuphuhliso lweshishini lombhobho wentsimbi.

Ixesha lokuposa: Dec-17-2024